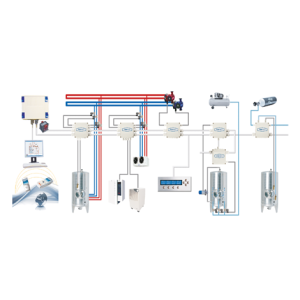

The elegant stainless-steel control cabinet FermFlex-Box serves to control tanks temperature automatically, from a central point in the wine cellar or in the brewery. For each tank to be controlled a FermFlex-Box control card is included. Therefore the temperatures of all tanks can be viewed at a glance and the settings can be changed on the spot.

The FermFlex-Box control unit receives its input through a cable-type sensor (available as an accessory) which is placed in the thermo-well of the respective tank. The controllers are designed in such a way that temperatures are optimally visualised: There are two separate displays for the pre-set temperature and the measured temperature (is temperature). The operation mode of the controller - cooling or heating - is indicated on a LED display. Moreover the control cabinet has two integrated relays for pump control: one for heating and one for cooling.

The FermFlex-Box control cabinets are equipped with a PC interface so that the temperature settings can be adjusted either physically on the cabinet or in the office using the Ferm-Software installed on a Server PC (option). Using the software allows easy and quick analysis of the measured data, data-saving of finished fermentations for later evaluation and archiving. Software access is enabled over lap-top and mobile phone over safe internet access. The new FermLine controllers can be locked by code – single units or the whole installation at once via BUS system - to prevent temperature modification by unauthorized personnel. The FermFlex-Box can also be completely integrated in the bus system VinInfo.

The cabinets are available inthree different sizes – for 10, for 20 or for 30 controllers (one controller per tank). With this new generation of FermFlex-Box it is possible to add more controllers afterwards if the maximum amount of controllers (10 / 20 / 30) is not needed for the initial installation.

CHARACTERISTICS

- Central control cabinet available in three sizes - for up to 10, 20 or 30 tank

- One pre-installed controller per tank

- Stainless steel casing

- Simple and clear operation

- Informative display with high contrast LED lighting for distance sighting. Simultaneous display of the measured and the set-temperatures, control-mode and the activity

- Temperature indication from -9,9 to +99,9°C, suitable for measuring high temperature processes such as pasteurization, beer mashing, sugar syrup for CSD etc.

- Two integrated collective relays for pump control: one for heating and one for cooling

- Integrated double safety chip for data protection during electric power-out

- With PC data interface for control over Ferm-Software

- Can be locked by code – a single controller or the whole installation at once

- Integration into the bus system VinInfo possible.

TECHNICAL DETAILS

- Controller:

- Temperature range: from -9,9 to +99,9°C (from 14,2 to 211,8°F)

- Output: 24V AC / 2,5A

- Regulation structure: 2-point (heating or cooling), 3-point (heating and cooling)

- Regulation mode: Cooling / Heating / Cooling & Heating / Display / Off

- Control cabinet:

- Power supply: 230V / 1Ph / 50/60Hz

- Protection type: IP55

- Chilly Max 50

- Chilly Max 90

- Chilly Max 110

- EP 54

- EP 84

- EP 104

- EP 124

- EP 154