Destemmers and crushers Delta E / F

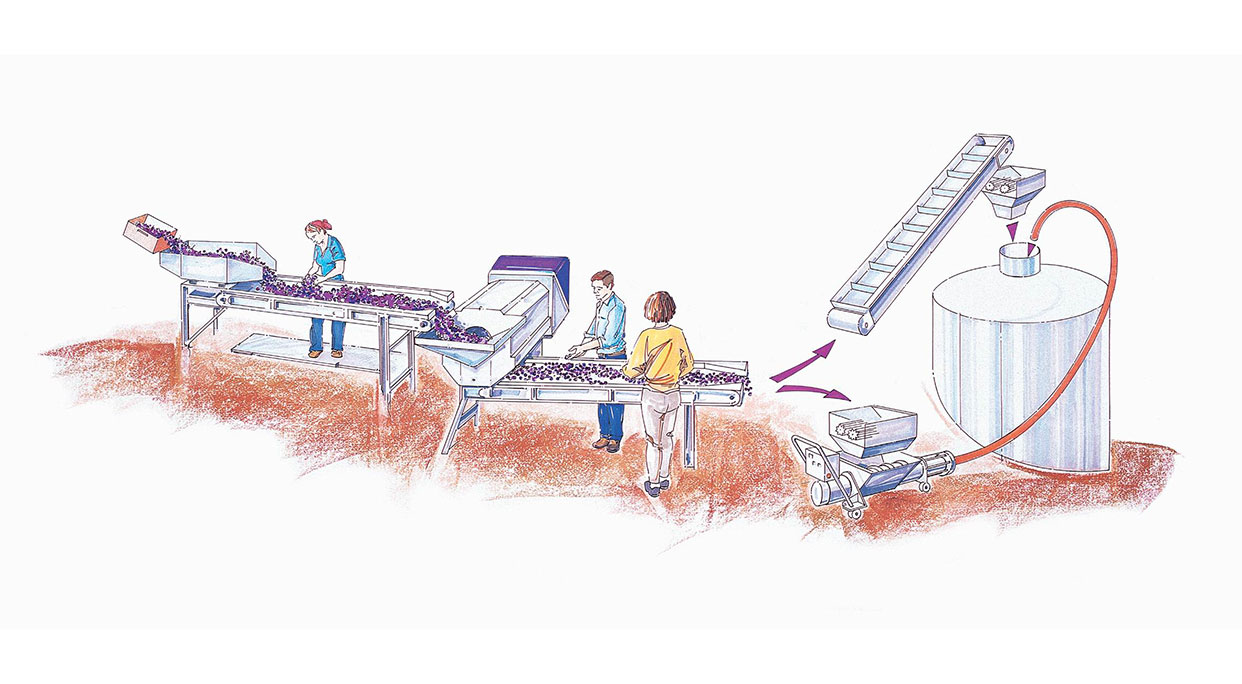

Poured into the hopper, the grapes are then gradually and gently conveyed according to a pre-set destemming speed. In see full description

Gentle processing

Poured into the hopper, the grapes are then gradually and gently conveyed according to a pre-set destemming speed. In this zone, the cage has no holes and clusters are taken by the beater fingers without bursting the berries or grinding them. In the destemming zone, the holes of the electropolished stainless steel cage have been designed with deep and round edges (5 mm for E2 and E4, 6,5 mm for E6 and E8). The shaft is equipped with paddles whose extremity is enlarged and rubberized (E2 and E4) or in stainless steel (E6 and E8). The stress applied on the grapes is therefore better distributed. The berries remain intact, the stems progress easily along the cage. The cage and the beater rotate in the same direction, avoiding the grapes shearing effects. In the destemming area, the paddles number is doubled for E2 and E4. Part of those paddles can be dismounted, one out of two for example for E2 and E4. The length of destemming area is then adjustable according to the grape variety and grape maturity. Destemming is more efficient, without excessive beating of the stems. All the driving elements are grouped in a rear tilting unit that are totally separated from the berries and juice circulation area and do not disturb handlings that can be made around the destemmer.

Multi purposes

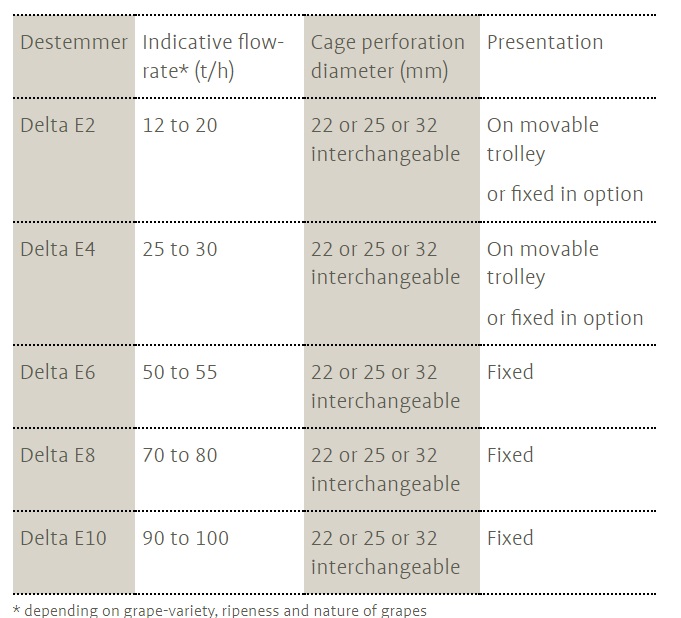

Three models of cage, adapted to the average berry diameter thus to the grape variety, are available. They can be easily and rapidly changed. The rotating speed of the separating unit (beater + cage) is adjustable and can be controlled through an electronic variator (E2 and E4). The machine installation is very easy. The destemmer can be set on a support, giving entire access to the lower part of the machine, or can be fixed on wheels. The wheels leave enough space for the pump to be set under the destemmer (E2 and E4).

Hygiene

The washing of the machine is carried out thanks to rotative water guns located at the upper part of the cage. The electropolished cage makes the washing easier. Indeed the specific treatment of the stainless steel limits the grip of materials (Potassium bitartrate, colour…). Side covers allow access to the cage, to the beater and to the evacuation hopper making the checking of the washing quality easier.

Maintenance and security

Handlings and adjustments are easy. The access to the separating elements is made possible by simply lifting the rear part. The changing of the cage and the beater can be rapidly carried out. The security is also important. Any handling of the side covers or the rear tilting unit stops the machine automatically.