Closed storage tanks for distilleries. Stainless Steel AISI304 (1.4301), mirror polished inside (BA/IIId), circle polished outside Tanks are suitable for fermentation as a preparation for further distillation and for storage of distillates.

Standard equipment

- welded legs

- 2 × cooling jacket (up to 4850 L) or 3 × cooling jacket (from 5150 L)

- 4 × fitting for cooling/heating ½’’ (up to 4850 L) or 6 × fitting (from 5150 L)

- bottom outlet with ball valve DN65 (up to 4850 L) or DN80 (from 5150 L)

- oval manway

- manhole Ø385 mm

- flange for agitator

- sample tap DN15

- analog thermometer

- thermowell (behind)

- spray ball (CIP) with tube DN32

- tube for filling DN65 (from 3850 L)

- ladder support

Additional equipment

- ball or butterfly valves – DN, WG, garolla, TC, macon

- blind nut with chain

- agitator

- additional spray ball with tube DN32

- adjustable feet

- lower tap ¾’’

- lifting lugs

- type plate

|

Volume in liters |

Dimensions in millimeters |

CJ in m² |

Code |

||||||||||

|

D |

H |

h1 |

h2 |

h3 |

h4 |

h5 |

Y |

Y1 |

Z |

Z1 |

|||

|

1100 |

955 |

2150 |

1500 |

400 |

800 |

280 |

750 |

150 |

500 |

300 |

300 |

1.6 |

10D1100L |

|

1500 |

1113 |

2150 |

1500 |

400 |

800 |

280 |

750 |

150 |

500 |

300 |

300 |

1.8 |

10D1500L |

|

2000 |

1267 |

2150 |

1500 |

400 |

800 |

280 |

750 |

150 |

500 |

300 |

300 |

2.3 |

10D2000L |

|

2450 |

1433 |

2150 |

1500 |

400 |

800 |

280 |

750 |

150 |

500 |

300 |

300 |

2.6 |

10D2450L |

|

2600 |

1272 |

2650 |

2000 |

400 |

950 |

280 |

850 |

400 |

550 |

400 |

400 |

2.9 |

10D2600L |

|

3300 |

1433 |

2650 |

2000 |

400 |

950 |

280 |

850 |

400 |

550 |

400 |

400 |

3.3 |

10D3300L |

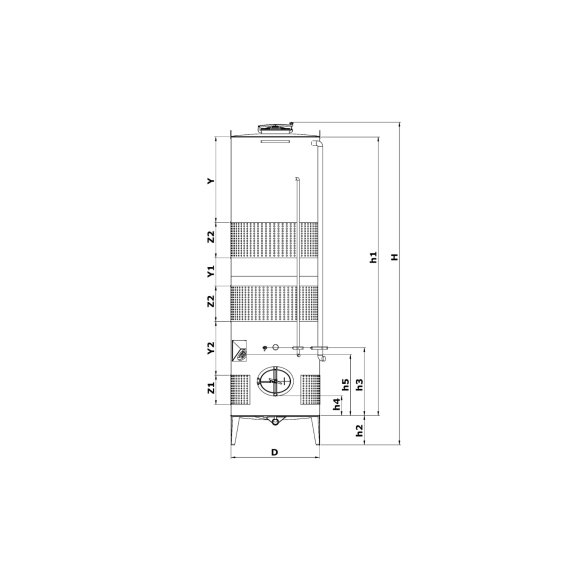

Scheme 1

|

Volume in liters |

Dimensions in millimeters |

CJ in m² |

Code |

||||||||||

|

|

D |

H |

h1 |

h2 |

h3 |

h4 |

h5 |

Y |

Y1 |

Z1 |

Z2 |

||

|

3850 |

1267 |

3650 |

3000 | 400 | 1000 |

280 |

800 |

750 |

1100 |

400 |

500 |

3.2 |

10D3850L |

|

4850 |

1433 |

3650 |

3000 |

400 |

1000 |

280 |

800 |

750 |

1100 |

400 |

500 |

3.8 |

10D4850L |

Scheme 2

|

Volume in liters |

Dimensions in millimeters |

CJ in m² |

Code |

|||||||||||

|

D |

H |

h1 |

h2 |

h3 |

h4 |

h5 |

Y |

Y1 |

Y2 |

Z1 |

Z2 |

|||

|

5150 |

1267 |

4650 |

4000 |

400 |

1000 |

280 |

850 |

850 |

700 |

600 |

500 |

600 |

6.5 |

10D5150L |

|

5800 |

1267 |

5150 |

4500 |

400 |

1000 |

280 |

850 |

750 |

900 |

1000 |

500 |

600 |

6.5 |

10D5800L |

|

6400 |

1433 |

4650 |

4000 |

400 |

1000 |

280 |

850 |

850 |

700 |

600 |

500 |

600 |

7.4 |

10D6400L |

|

8000 |

1592 |

4650 |

4000 |

400 |

1000 |

280 |

850 |

850 |

700 |

600 |

500 |

600 |

8.3 |

10D8000L |

|

10000 |

1592 |

5650 |

5000 |

400 |

1000 |

280 |

850 |

550 |

700 |

1500 |

500 |

800 |

9.6 |

10D10000L |

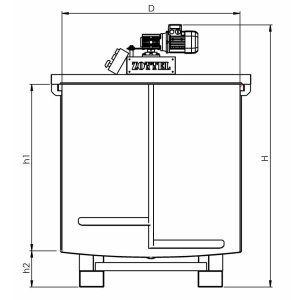

Scheme 3

- 300 litrów

- 500 litrów

- 800 litrów

- 1100 litrów

- 1500 litrów

- 2000 litrów

- 2450 litrów

- 2600 litrów

- 3300 litrów

- 300 liters

- 500 liters

- 600 liters

- 800 liters

- 1100 liters

- 1500 liters

- 2000 liters

- 2450 liters

- 2600 liters

- 3300 liters

- 500 litres

- 600 litres

- 800 litres

- 1100 litres

- 1500 litres

- 2000 litres

- 2450 litres

- 2600 litres

- 3300 litres

- 50 liters

- 100 liters

- 150 liters

- 200 liters

- 250 liters

- 300 liters

- 380 liters

- 1100 liters

- 1500 liters

- 2000 liters

- 2450 liters

- 2600 liters

- 3300 liters

- 3850 liters

- 4850 litrów

Stainless Steel AISI 304 (1.4301), Mirror polished inside (BA/IIId), Circle polished outside. Mixing tanks are intended for use in wine production. They

- 100 liters

- 150 liters

- 200 liters

- 250 liters

- 300 liters

- 380 liters

- 500 liters

- 600 liters

- 800 liters

- 1100 liters

- 1100 liters

- 1500 liters

- 2000 liters

- 2600 liters

- 3300 litrów

- 4000 liters